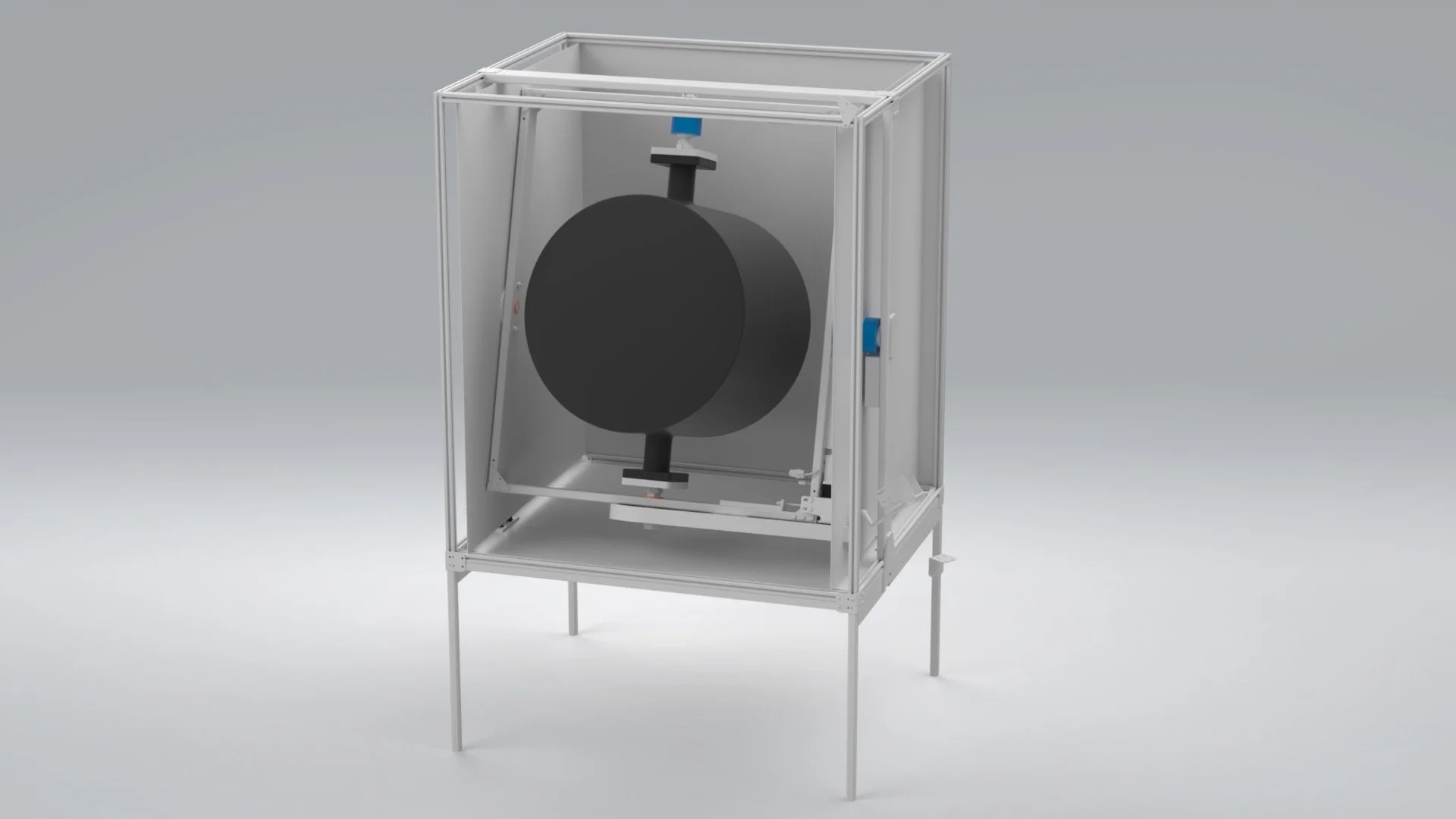

Solar Rotational Molder Lab

-

During my time at Light Manufacturing in Arroyo Grande, CA another intern and I co-led the concept-to-prototype build of this lab. This is a rotational molder that instead of using an oven to heat the plastic charge and series of heliostats aim sunlight to heat the mold. The mold is rotated about 2 axes with a belt-driven system.

-

Used Alibre to design

Preformed Stress and fatigue analyses, using FEA to verify critical members and joints

Designed around available manufacturing methods

Applied GD&T to all drawings

-

At the end of the summer we had a functional prototype that proved the viability for further development

Micro Turbo Jet

-

For a club project some friends and I decided we wanted to try a build a turbo jet engine. The goal was to achieve an idle rpm of 30 krpm. We believed there that the engine would self-sustain. I was in charge of the combustor and general housing design.

-

Used SolidWorks for design and MATLAB for analysis

Applied design equations from research

Iteratively designed through 2 engines

-

We designed and manufactured 2 engines, neither were able to achieve our desired results. However this project taught me about designing for manufacturing and assembly. I am still proud of this project, mainly because the people I worked with on it were fantastic.

Fluids System for Rocket Engine

-

Some students and I spent a quarter to develop a liquid rocket engine for the propulsions lab. I was in charge of the fluids system. I needed to design and assembly a fluids system to feed the oxidizer and fuel to the injector. This system had to last up to 10 years with minimal maintenance and be operable by students.

-

Given desired pressures and flow rates by the injector designer I back tracked pressure drops

Ordered parts through McMaster

Oxygen Cleaned parts and created documentation

-

The goals of the project were reached. The first hot fire was a success and students are currently using this system in their labs.

Topology Optimization

-

I spent sometime learning topology optimization under the guidance of a professor. This is a quick project I did to explore the methods and create something that I can use. I wanted to make a coat hanger that I would fit onto a shelf in my room.

-

Approximated loading

Defined a mesh and used FreeFem to apply topology optimization methods to that mesh

Then modeled the resulting geometry in SolidWorks

3D-printed the part

-

The coat hanger works, but more importantly I was able to apply topology optimization methods in be it a simple way.